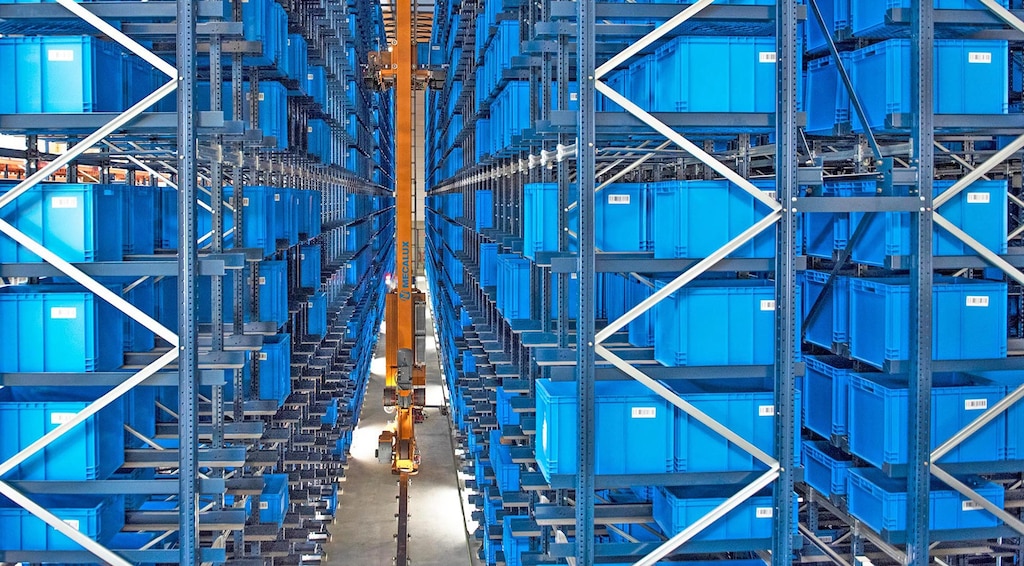

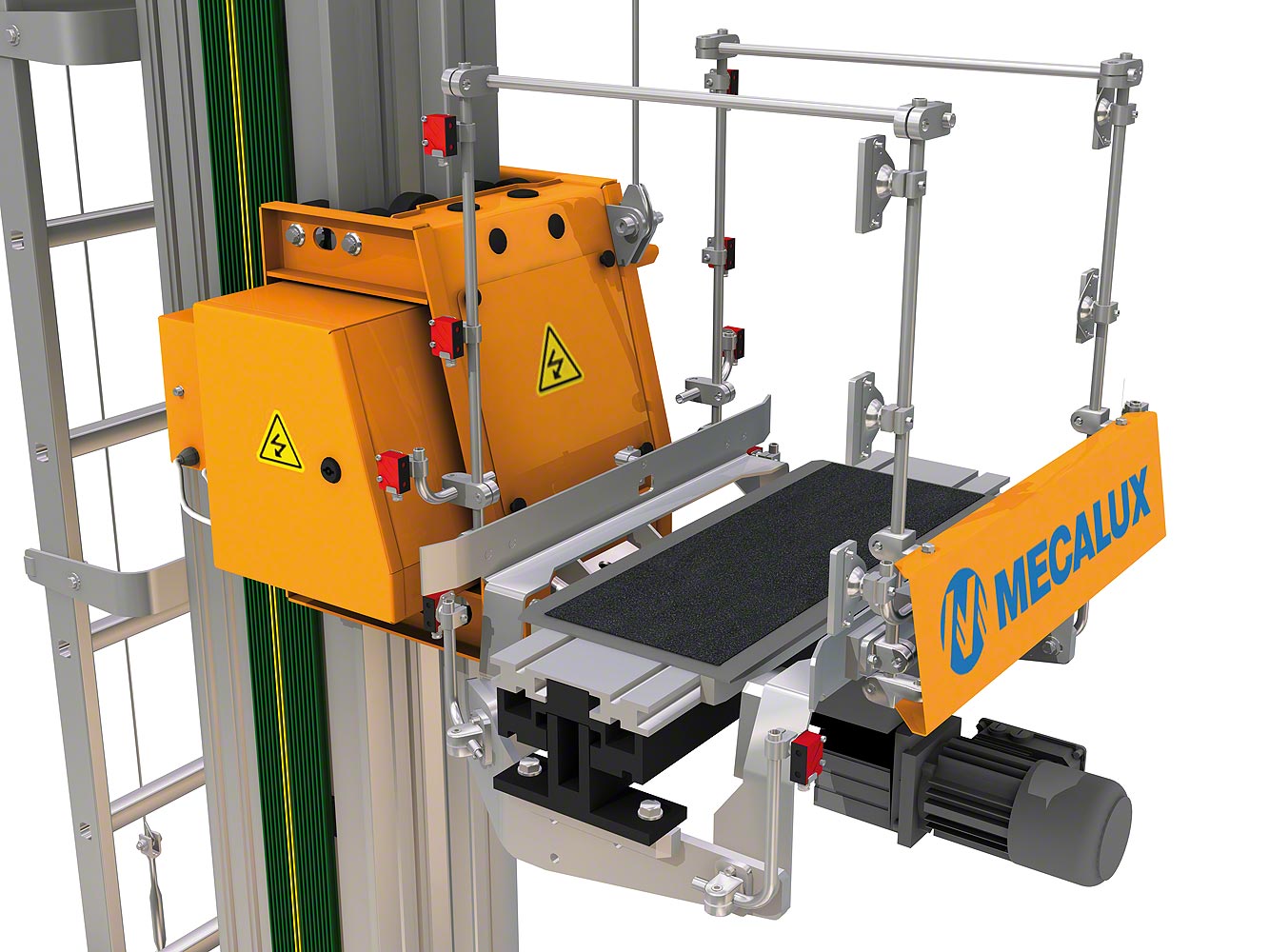

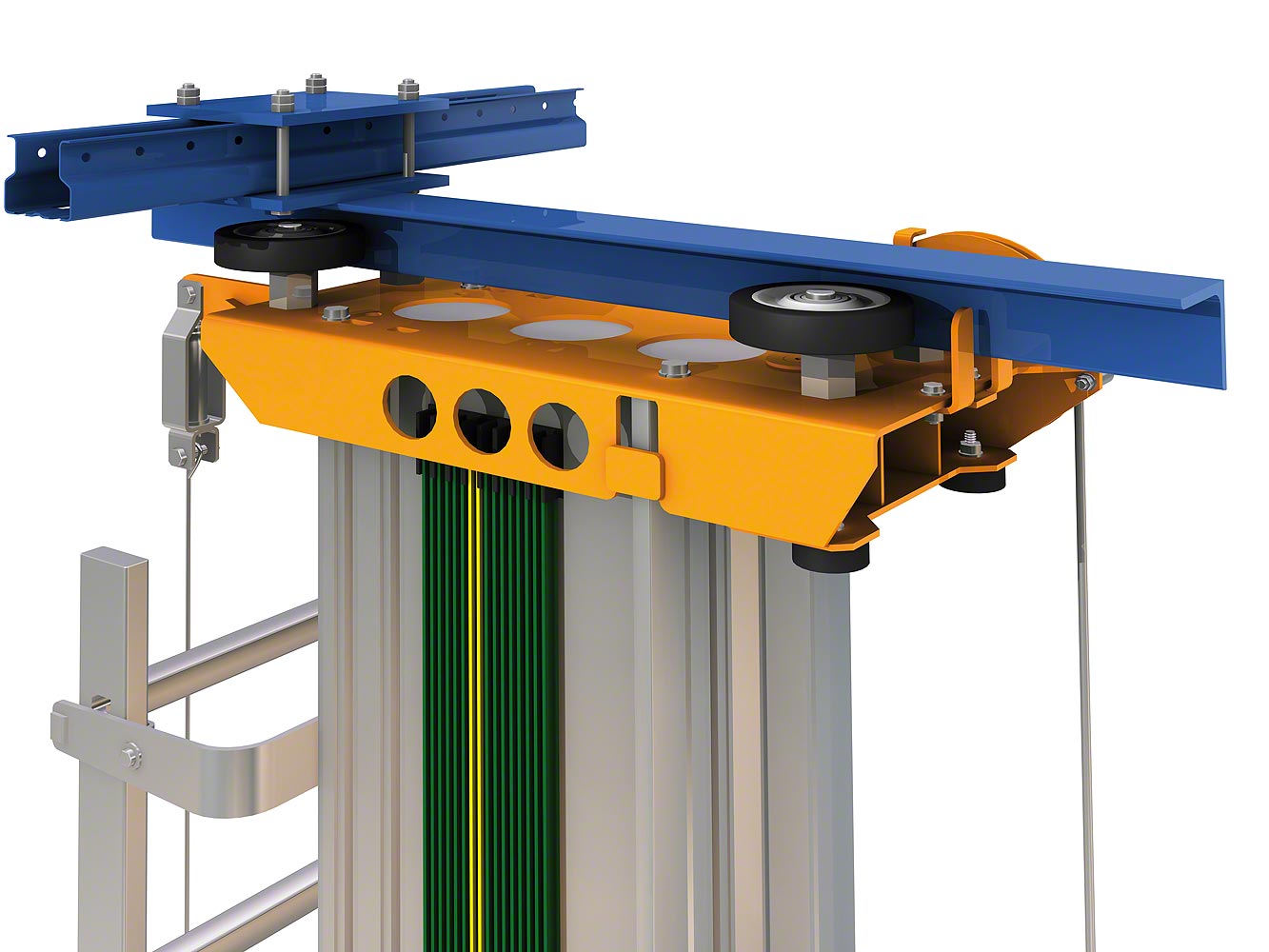

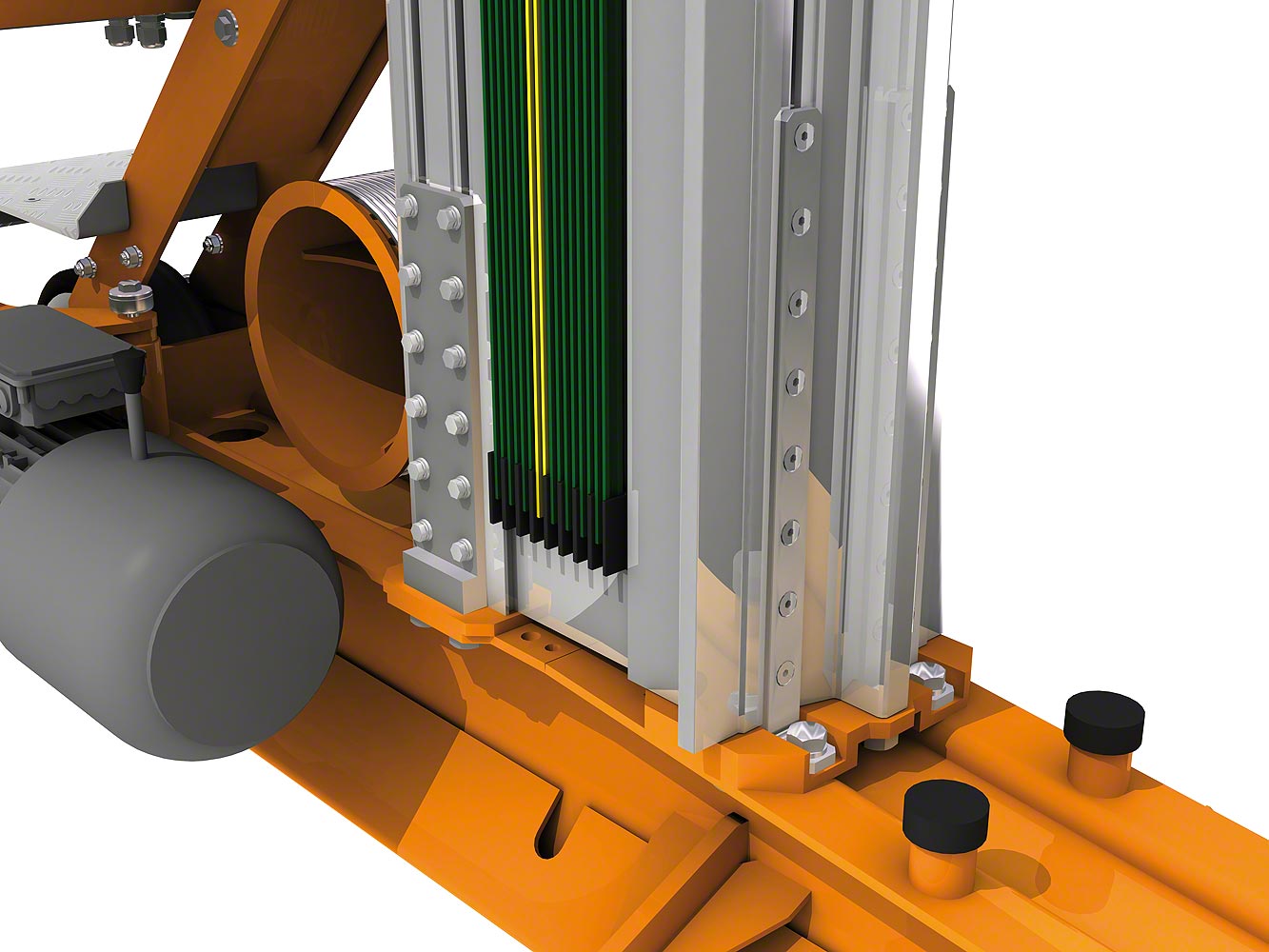

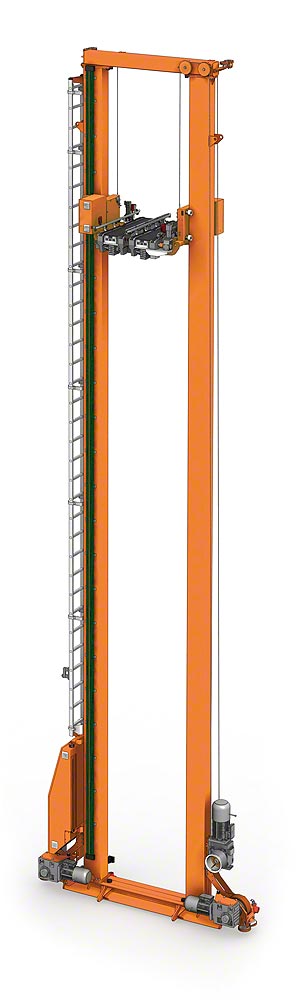

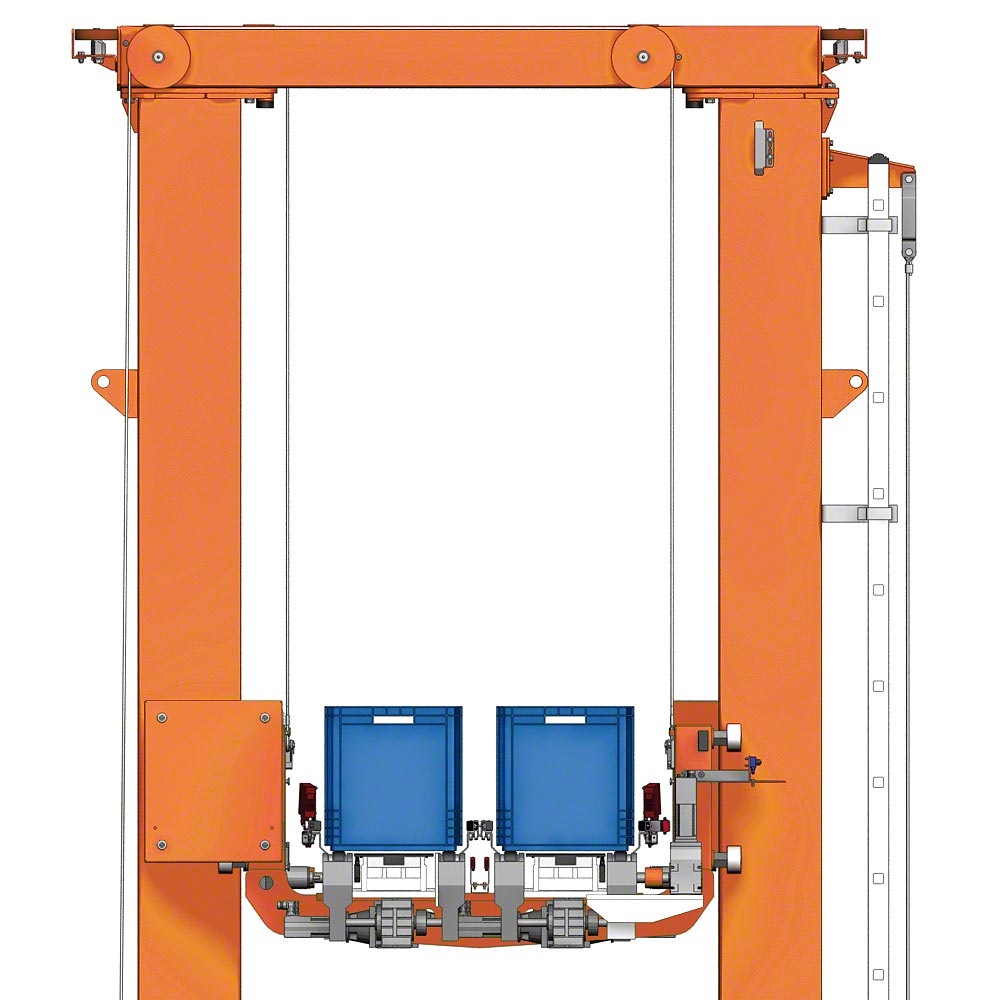

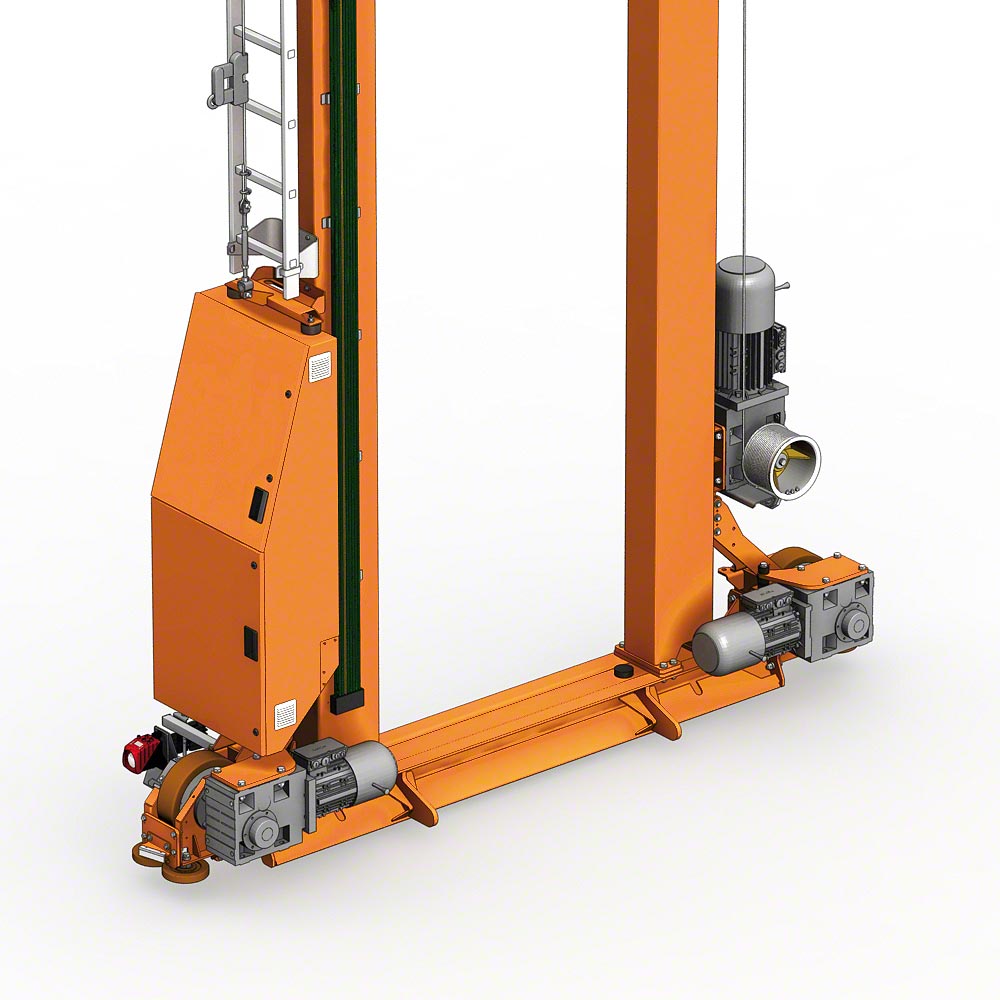

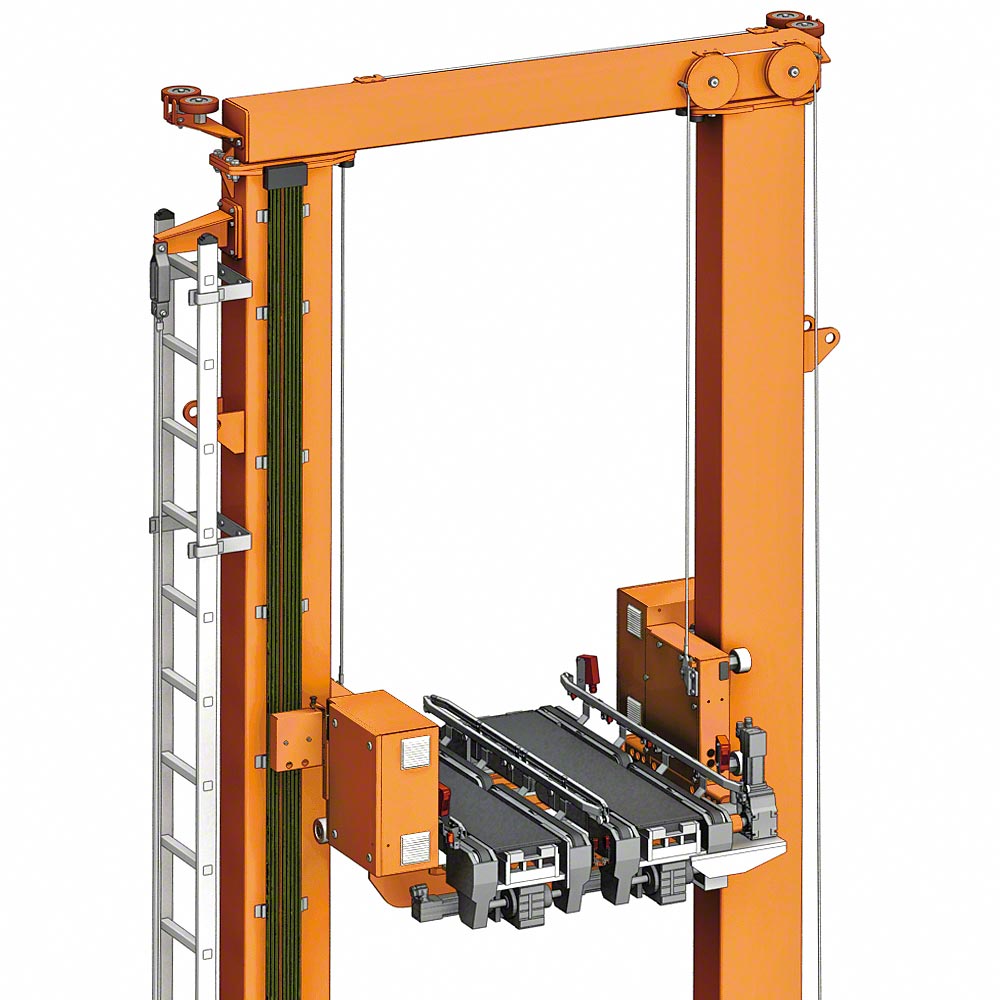

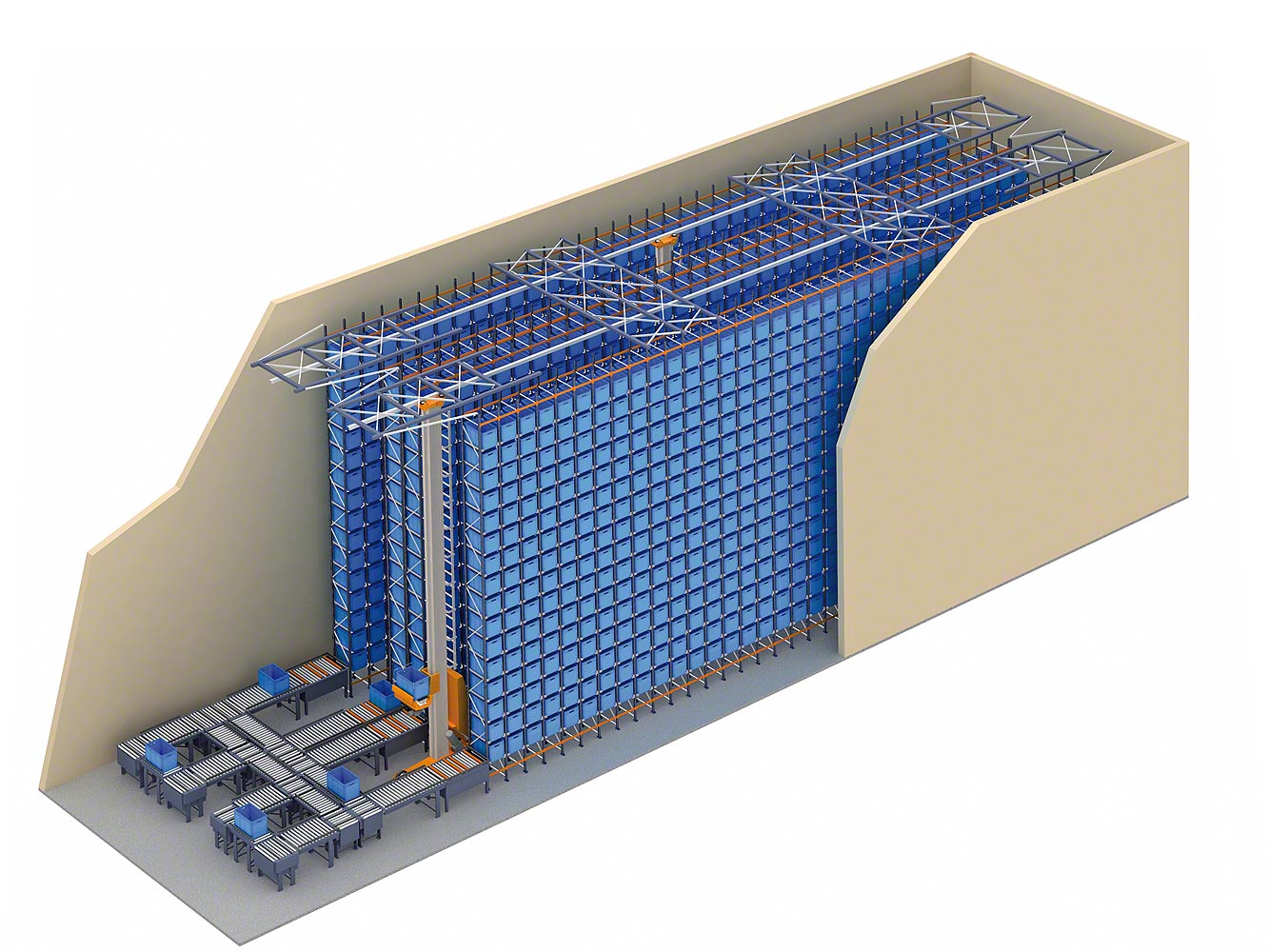

Stacker cranes for boxes

Automating receptions and dispatches. Large productivity. Permanent inventory. Error elimination. High performance in available space.

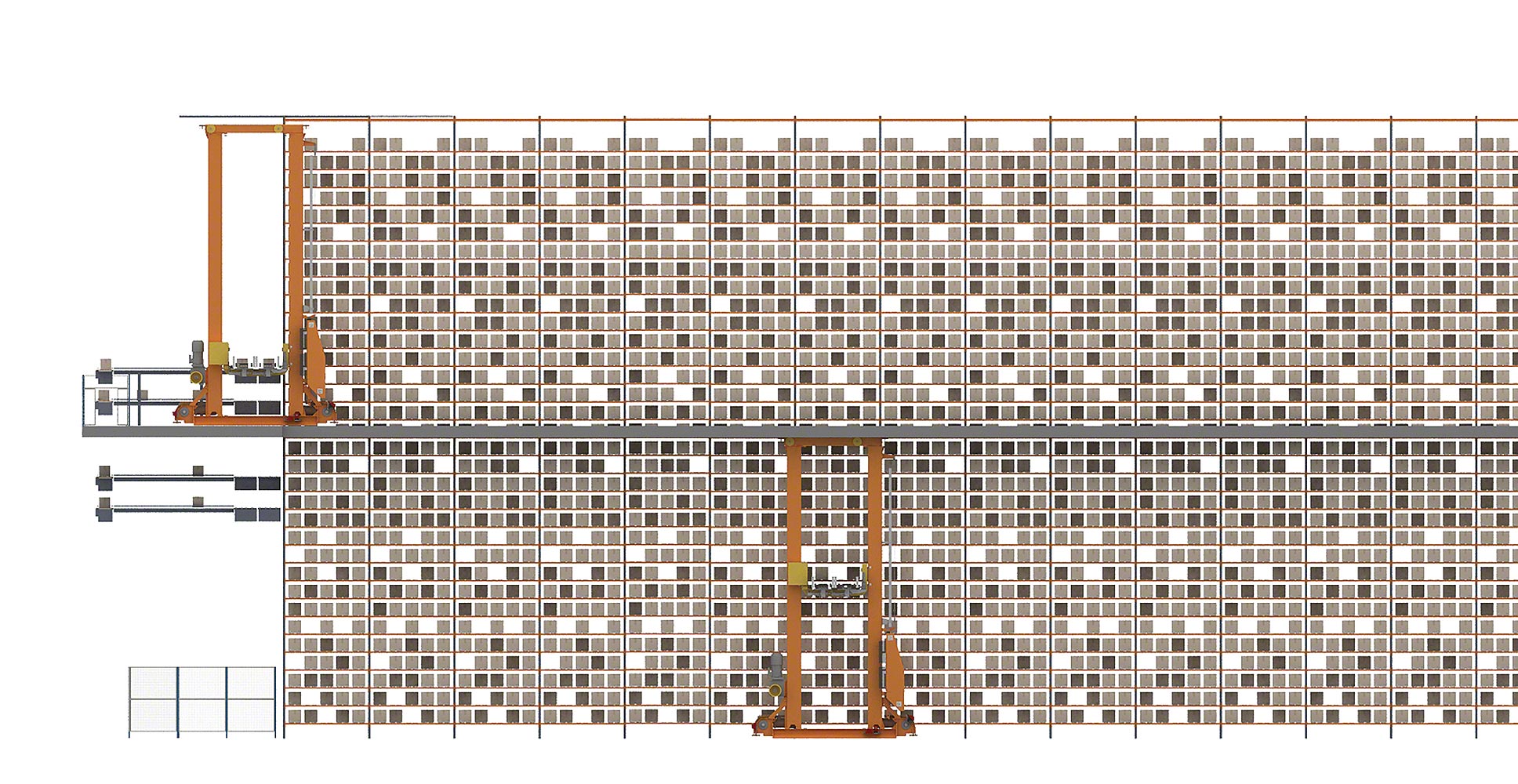

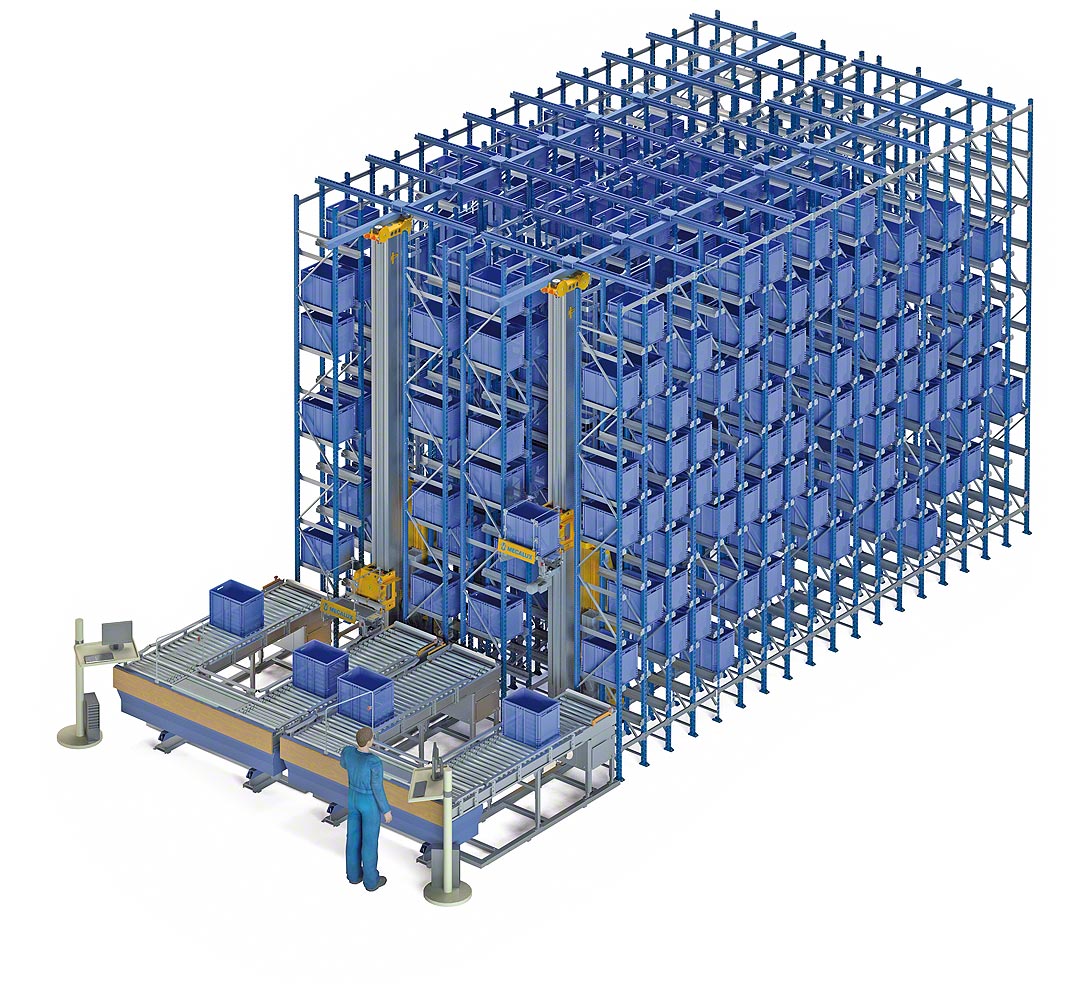

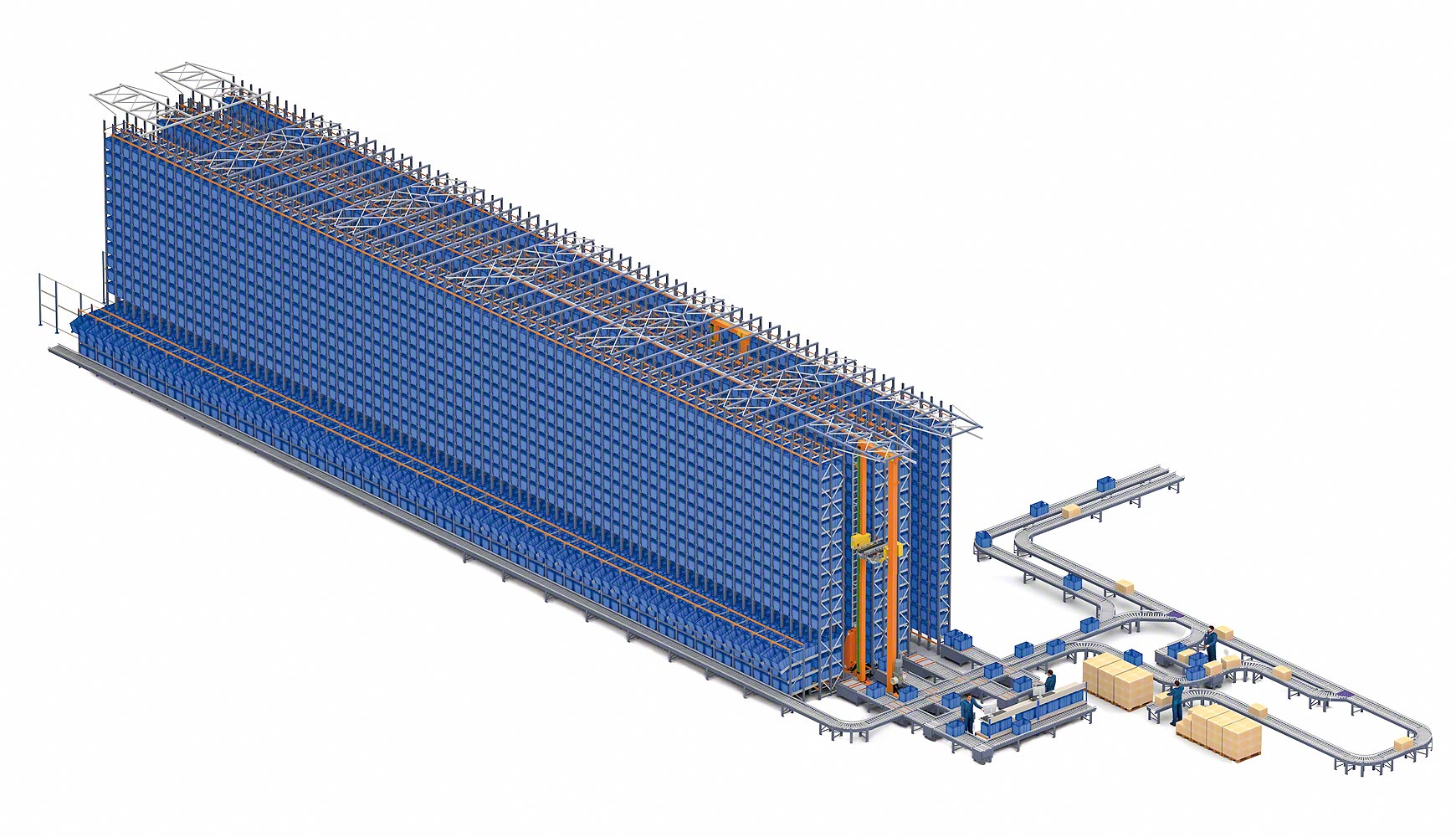

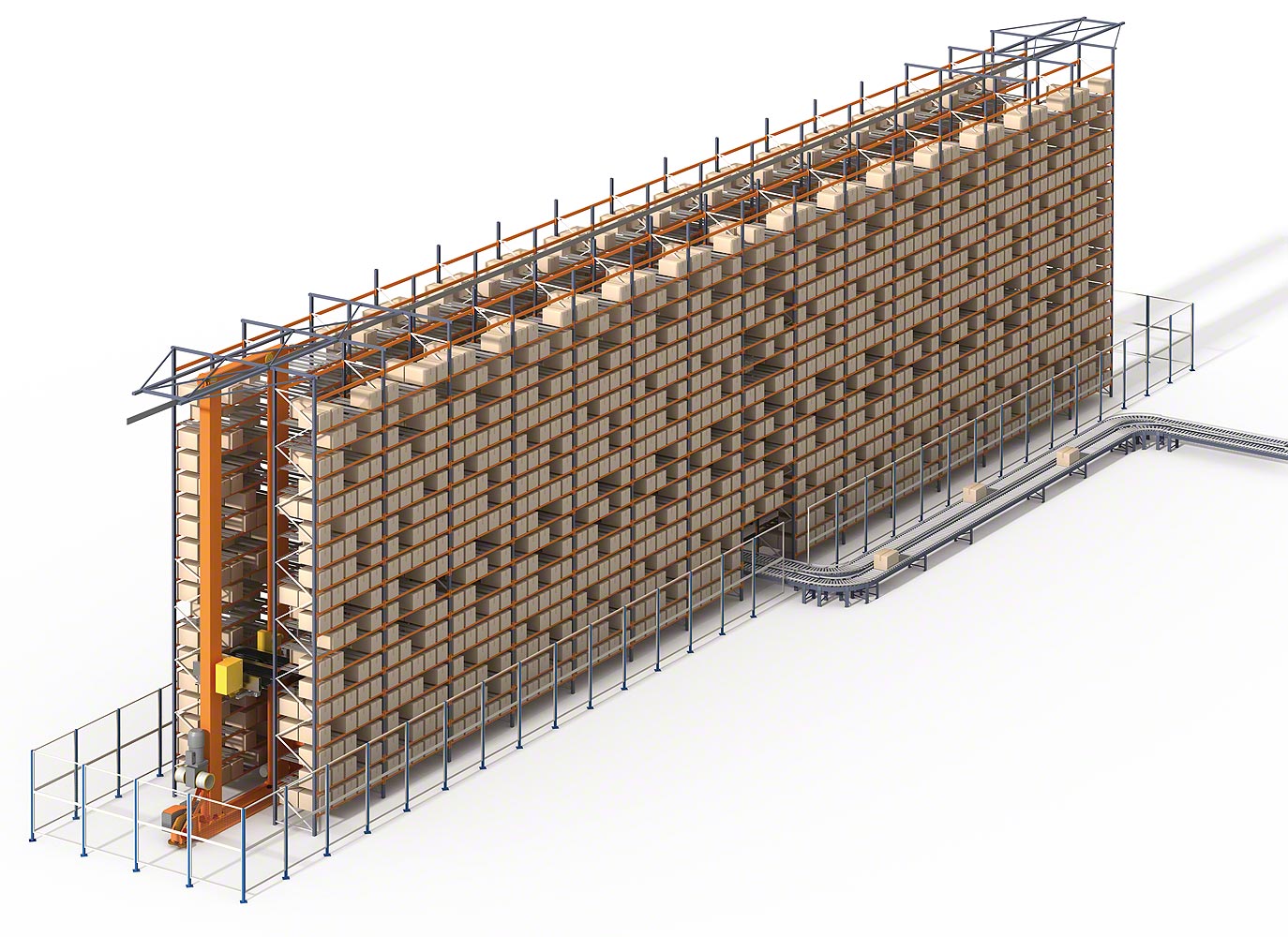

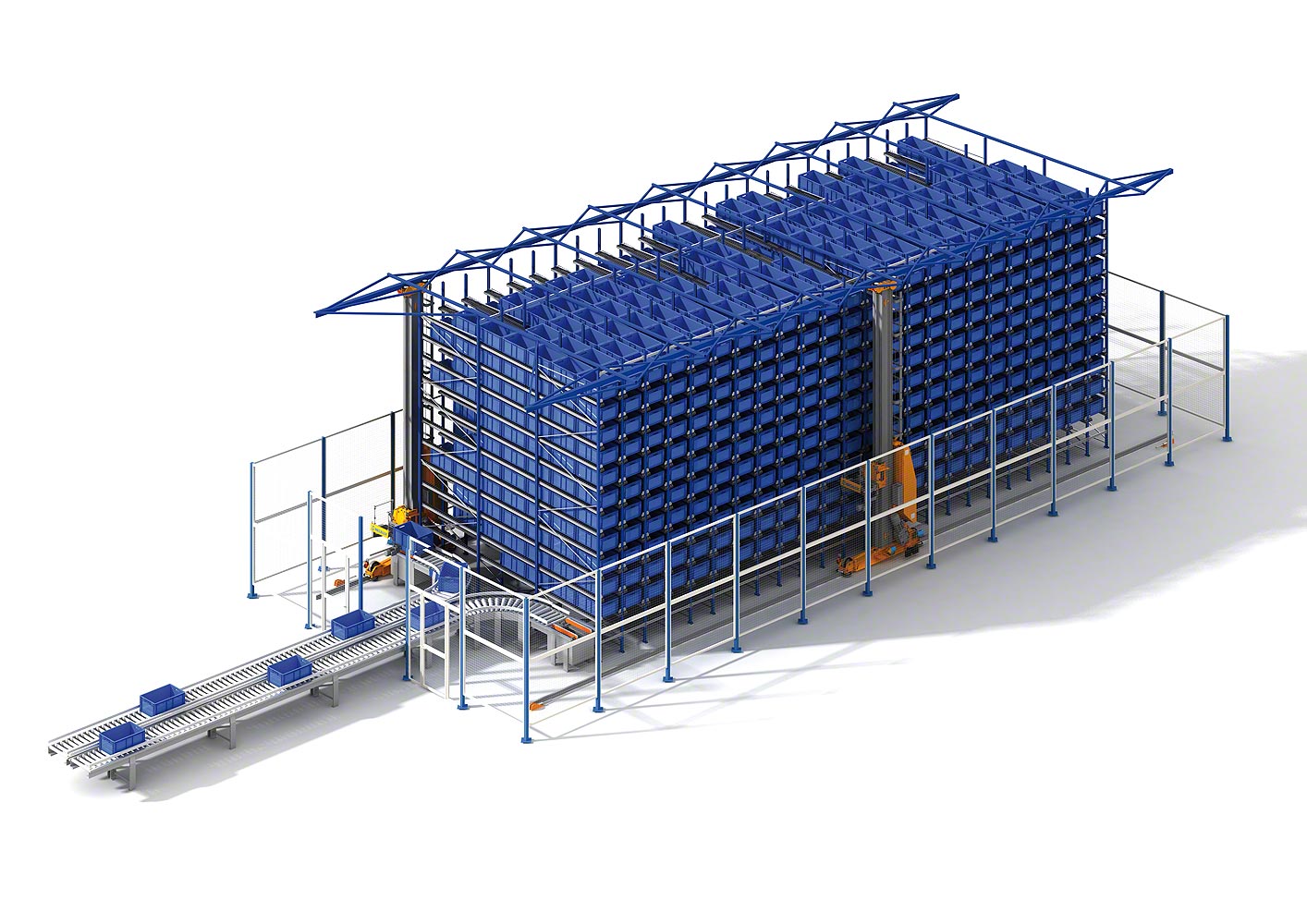

The Miniload (another name for the box stacker crane) can reach a height of 20 metres in an aisle width of only 800 mm.

12ba1041-4cb2-c613-24d2-4c75246b83ed

2e3730a9-499b-b0ac-f65b-f4f18fb4f607

1a7280d0-5204-d458-8e5c-1308c61b530c

a686c8c3-cb14-ea2c-b90a-e5e5842979d5

315ee82c-6f3f-3382-7a16-9ca3fbfad6f9

af6c93aa-deba-d9b5-70da-fad130d09a00

136a51b6-69d5-d50c-fda5-bd0f9fddc535

897af267-acb5-c7ce-a25d-f74bd755e7ee

67211507-2785-4ac5-da09-44e71b03355b

20aceaa8-5a74-dd89-f25f-fe466c230fb4

cd59ef18-a31c-e78e-9b89-79b63d38ee5b

fd0d4f23-8ae6-4f90-0234-f2700c64e16e

ea67c556-f994-af07-67cc-dabe61419824

02a830df-f093-4edb-7389-729e2a3039b4

e56526ea-4b6c-6bc7-7e2e-a1d34d4aa056

18874552-fd08-e33e-1e20-fd6b07e0a4e7

b08f5409-497c-8eaa-3f7a-653f9e6523b1

880ebde2-8b97-b421-6e7b-fd2f06c1eba3

94e0177c-f43b-3a9b-3ec4-7d60255d3036

55073640-f756-a11e-e350-1b406bb3fe02

658aefc2-6d7c-caf7-439e-0d9889f6aad6

d9bb15ef-4f15-69cc-a7f0-ff38aa5f301d

b4fe34a8-7094-c1e7-6a48-74cc7a0be2f8

2b7c1667-6489-2442-1348-aab2cd174ea2

7e7c5164-67e9-08e6-04e6-e4f5894bf928

53574132-612f-1162-b2d6-f3db1a886dca

4d7288b7-d0cb-beea-f87b-e525178febe9

b08f1e56-30e2-e7bd-680d-e036e71ca8b2

1af83852-c329-1d41-7553-8f7c61876f6d

c96f41ec-9e82-6c17-5fd7-44aede580a1f

c05f95da-7220-7515-ee1a-cccb610fca1c

31d3451f-47cc-4618-d712-6c851a167656

5228ff96-2701-6083-a1ec-9d5dcc55d4f7

fc8ed309-5f82-96fe-fb20-4cc21e623fad

dd2b40dc-9ee2-77c1-345f-0e784364a8ec

23eb636e-a9bf-e0db-b943-69d56d81124d

7593da69-0296-f0db-dd19-5de37f677f99

ff4768bf-6cb8-113e-4101-0441c47d8664

ee8d63c7-1082-e4fb-08d4-5ccad050a8f4

511f6e13-5d32-8957-cfe2-9e1975c9cacd

cec08ea7-204d-511a-7aa0-1c0d9934f816

da3f601f-9bdc-2857-a722-d1753b6291a5

2b80c40e-5b1e-8747-ebfd-952e238a44b8

1839b6ff-226d-a025-1721-b722b6782b03

2eb306d6-22d3-137b-7083-e9c92fc91d4b

6a60a8b9-8714-2872-0c38-5a2317490c03

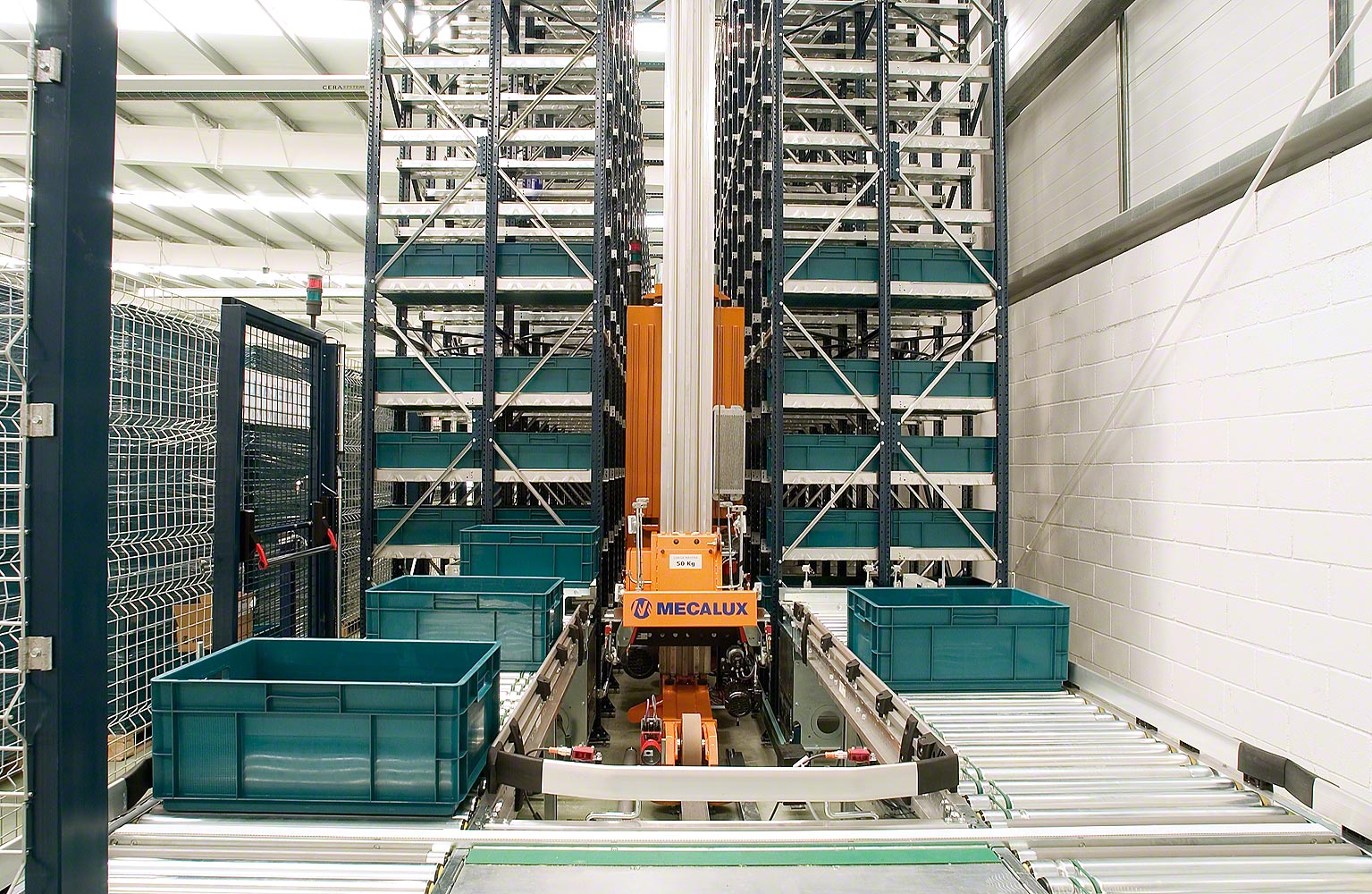

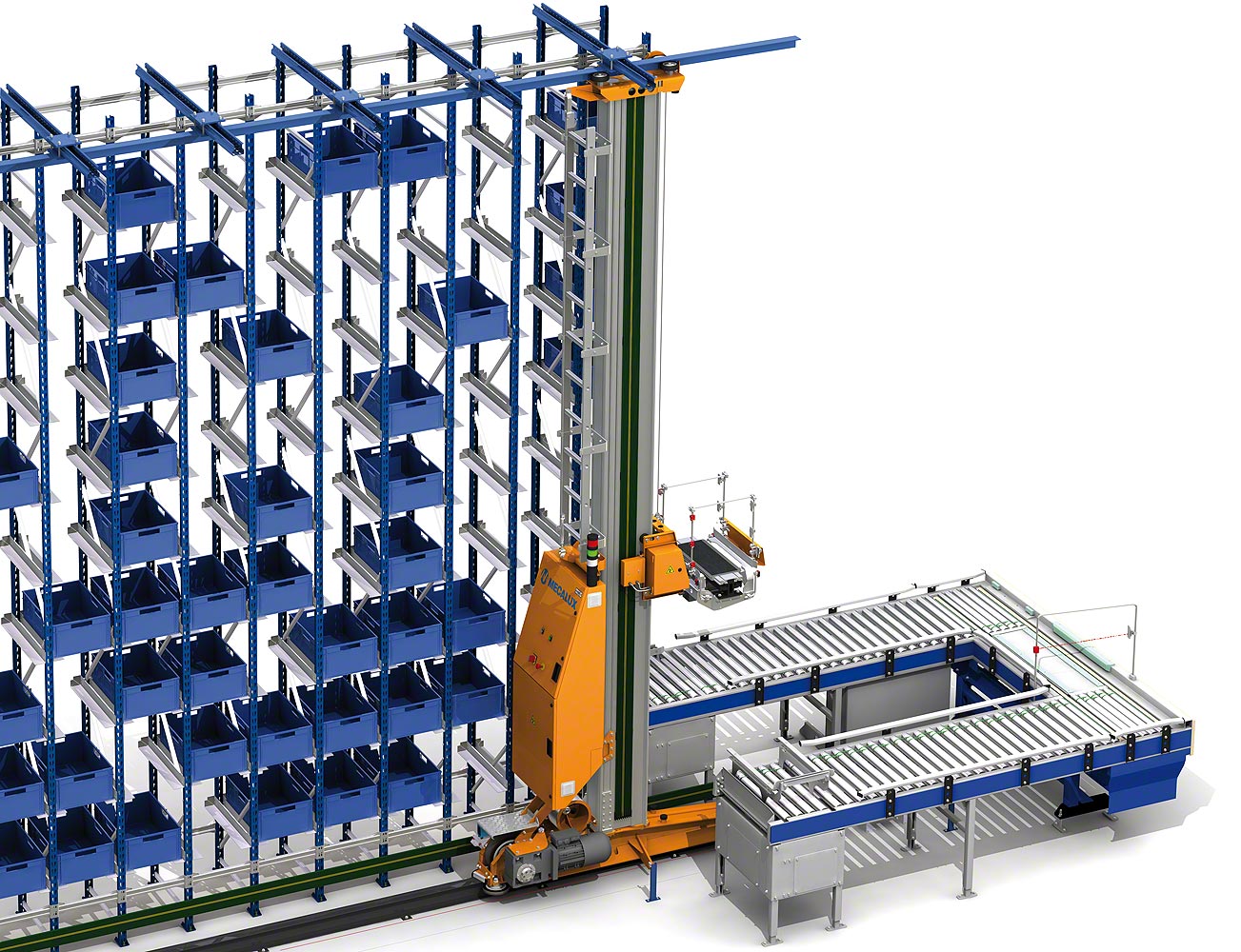

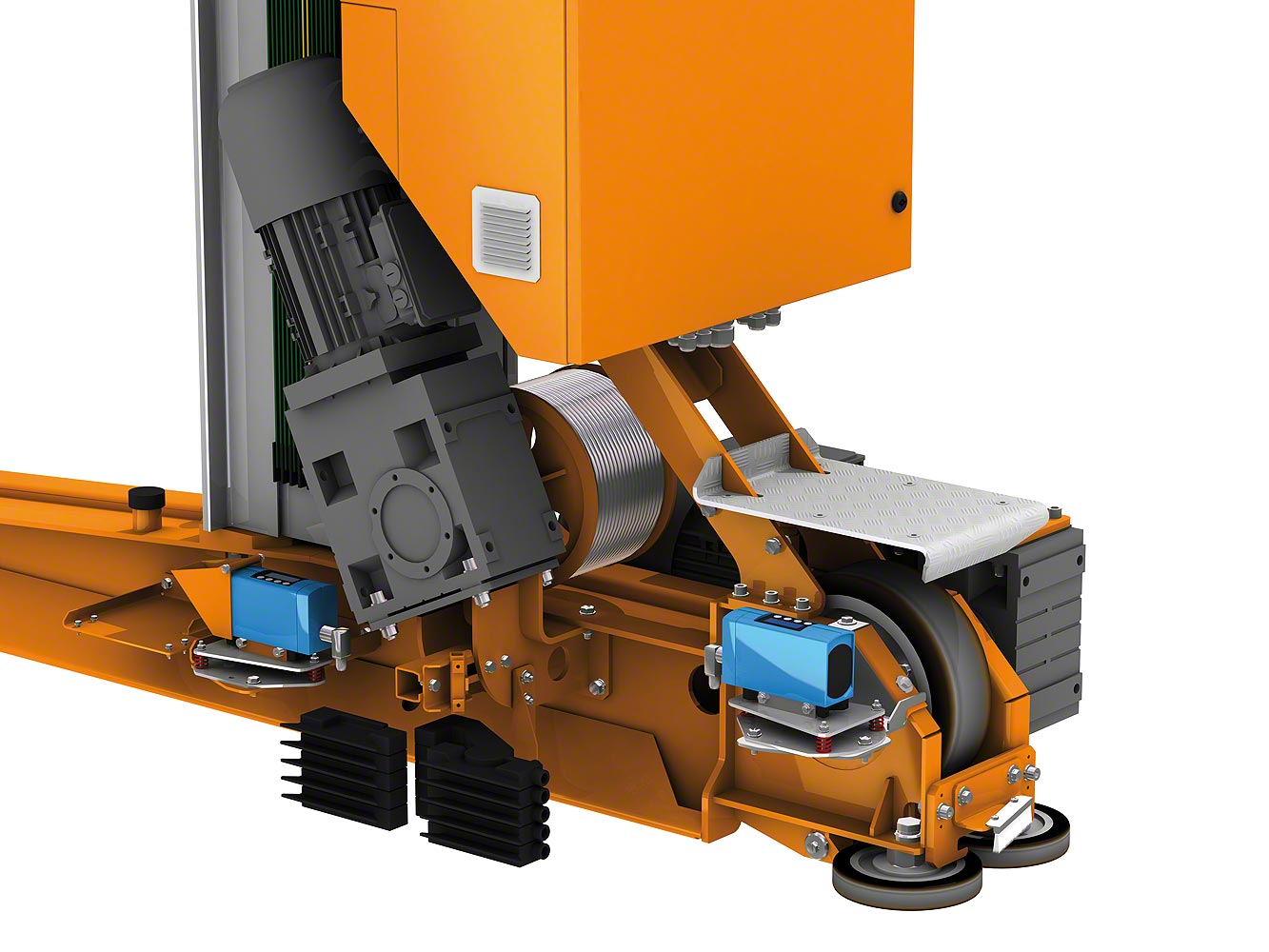

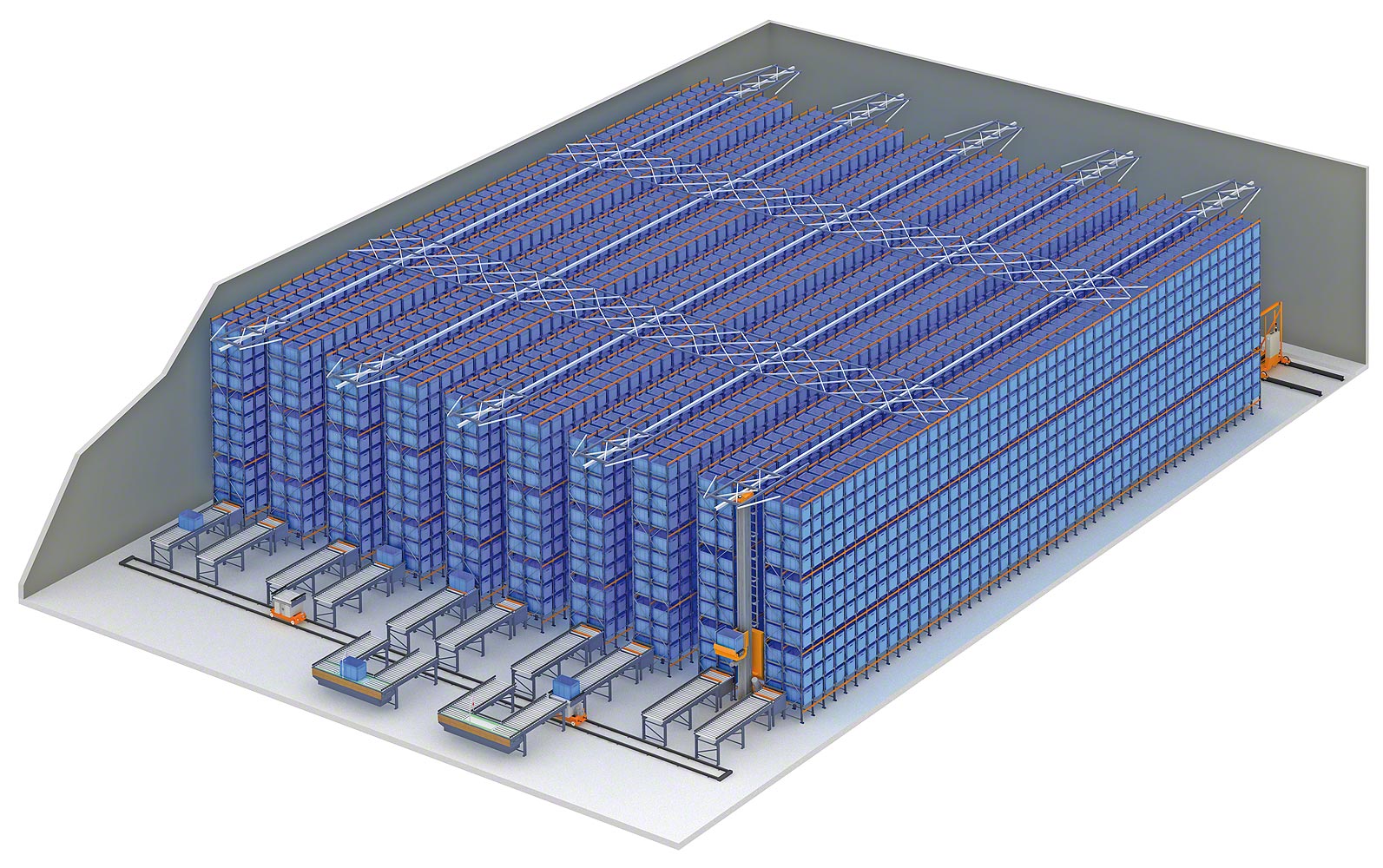

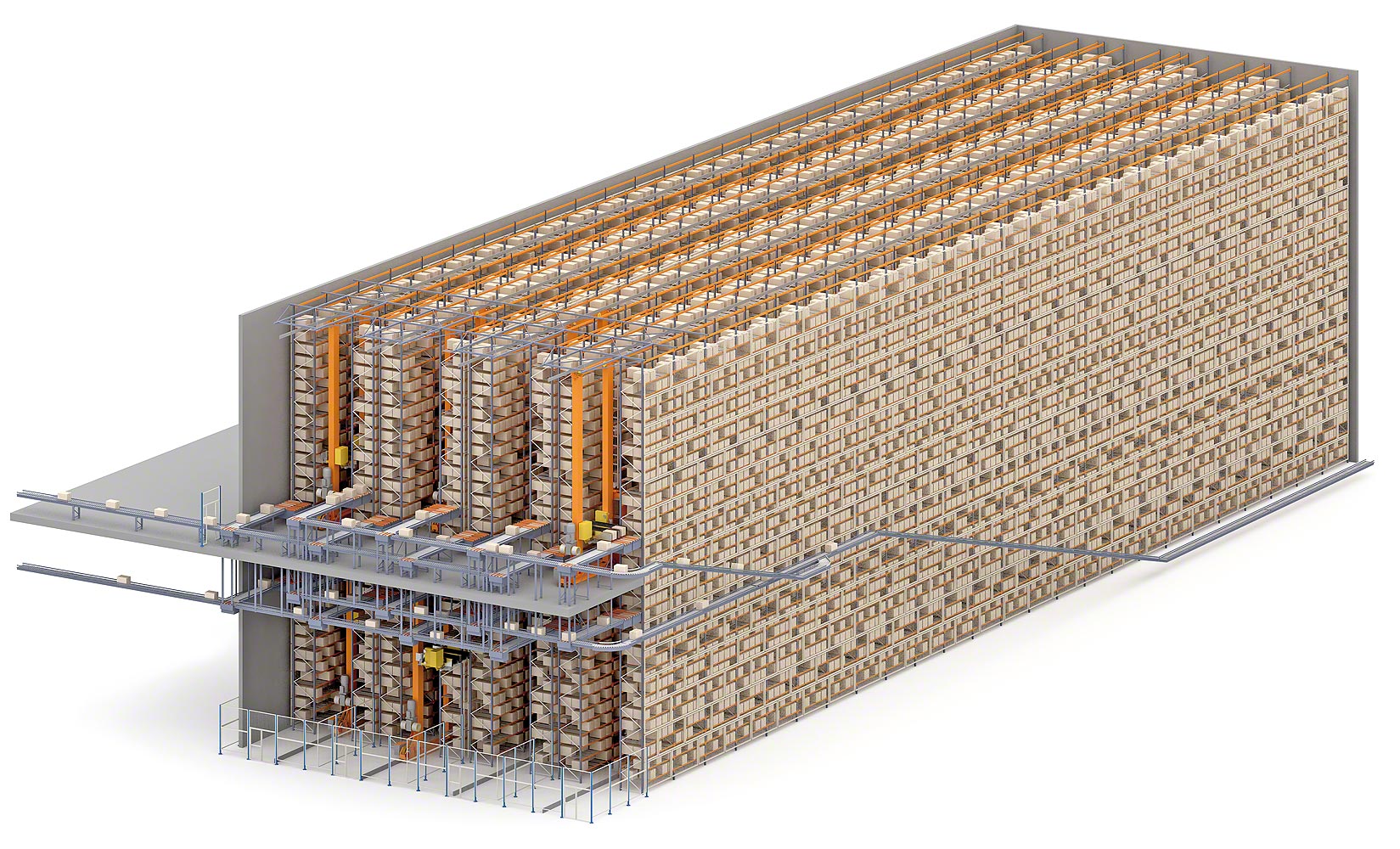

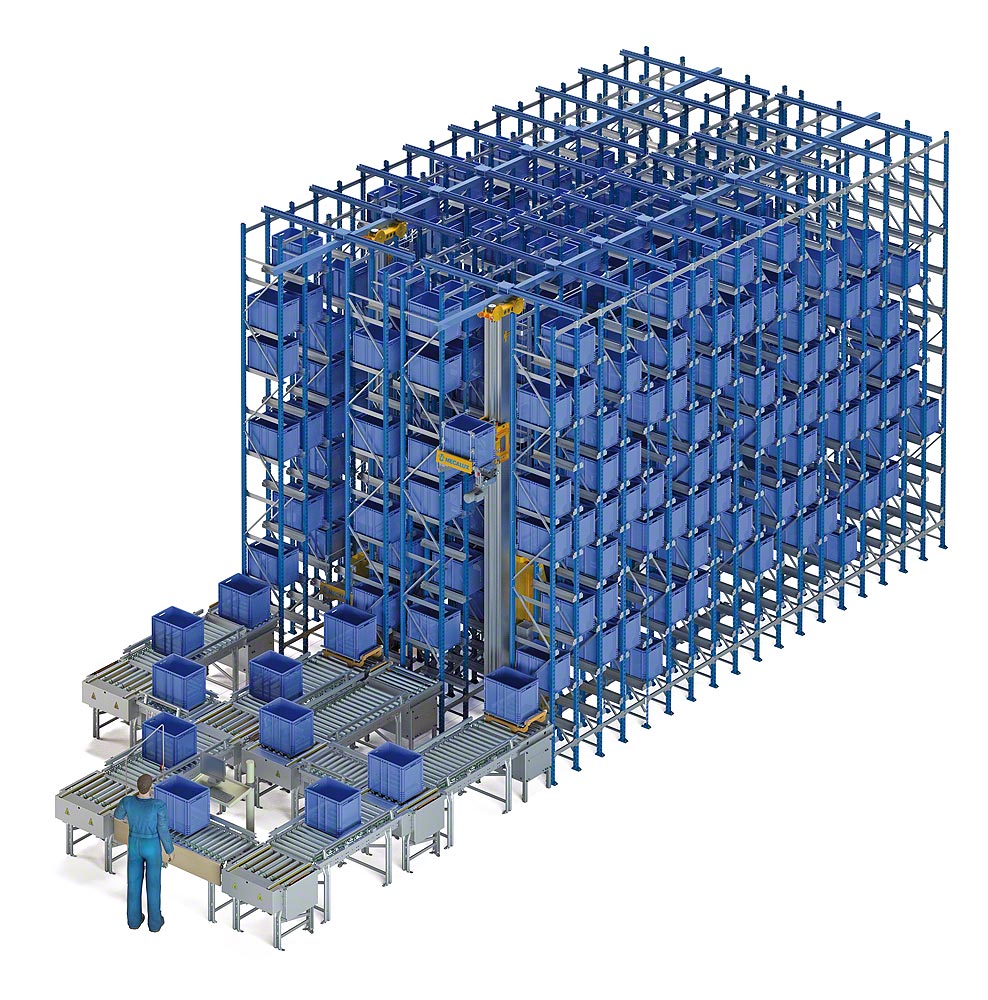

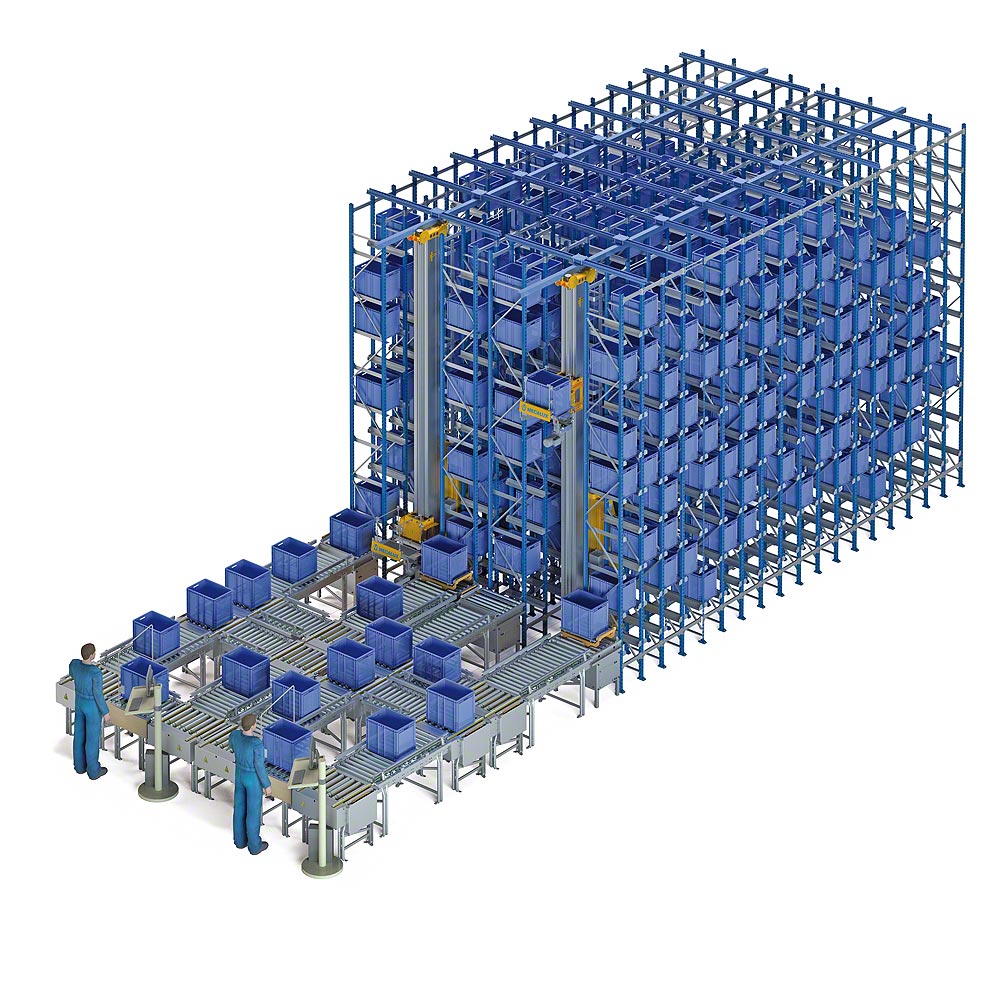

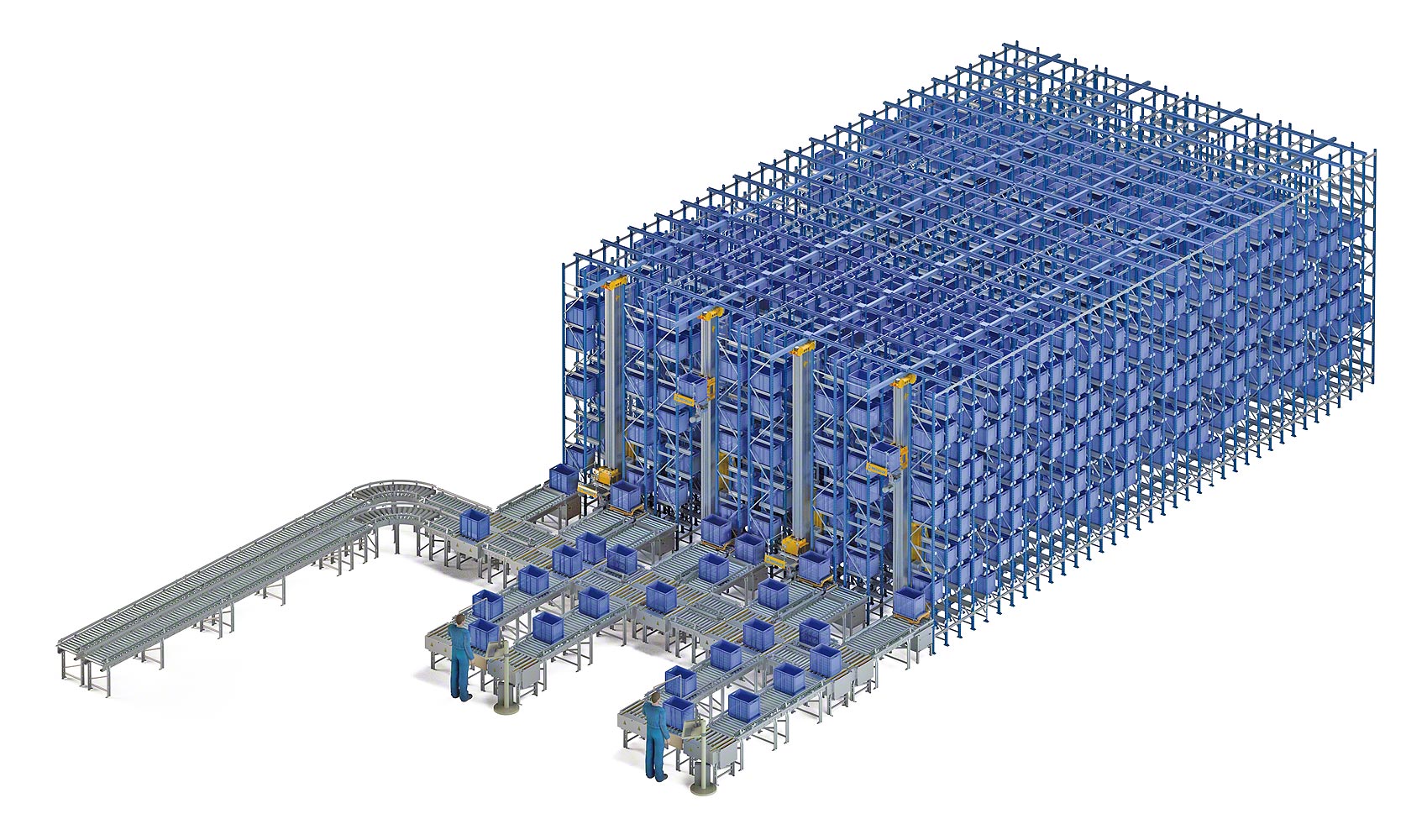

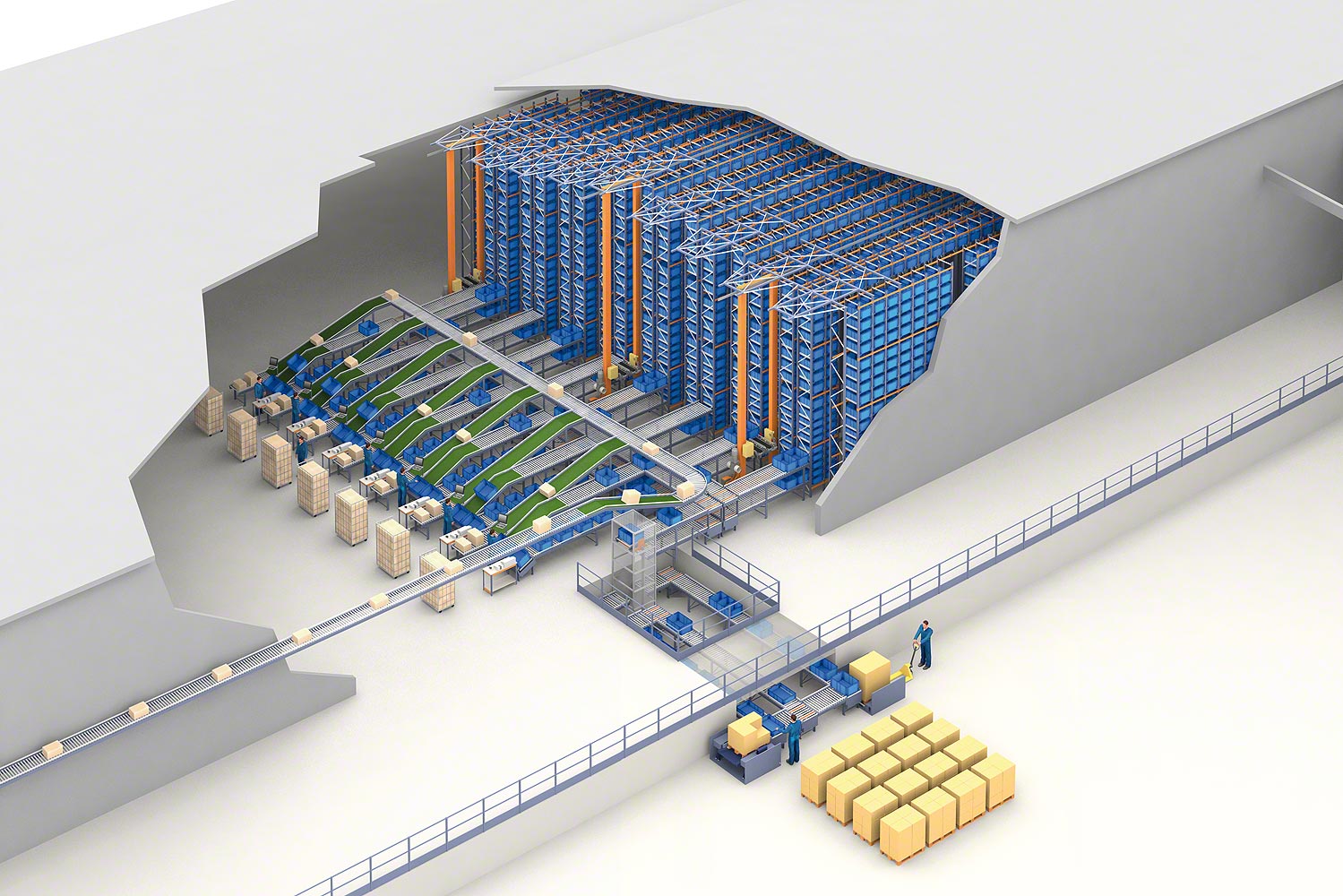

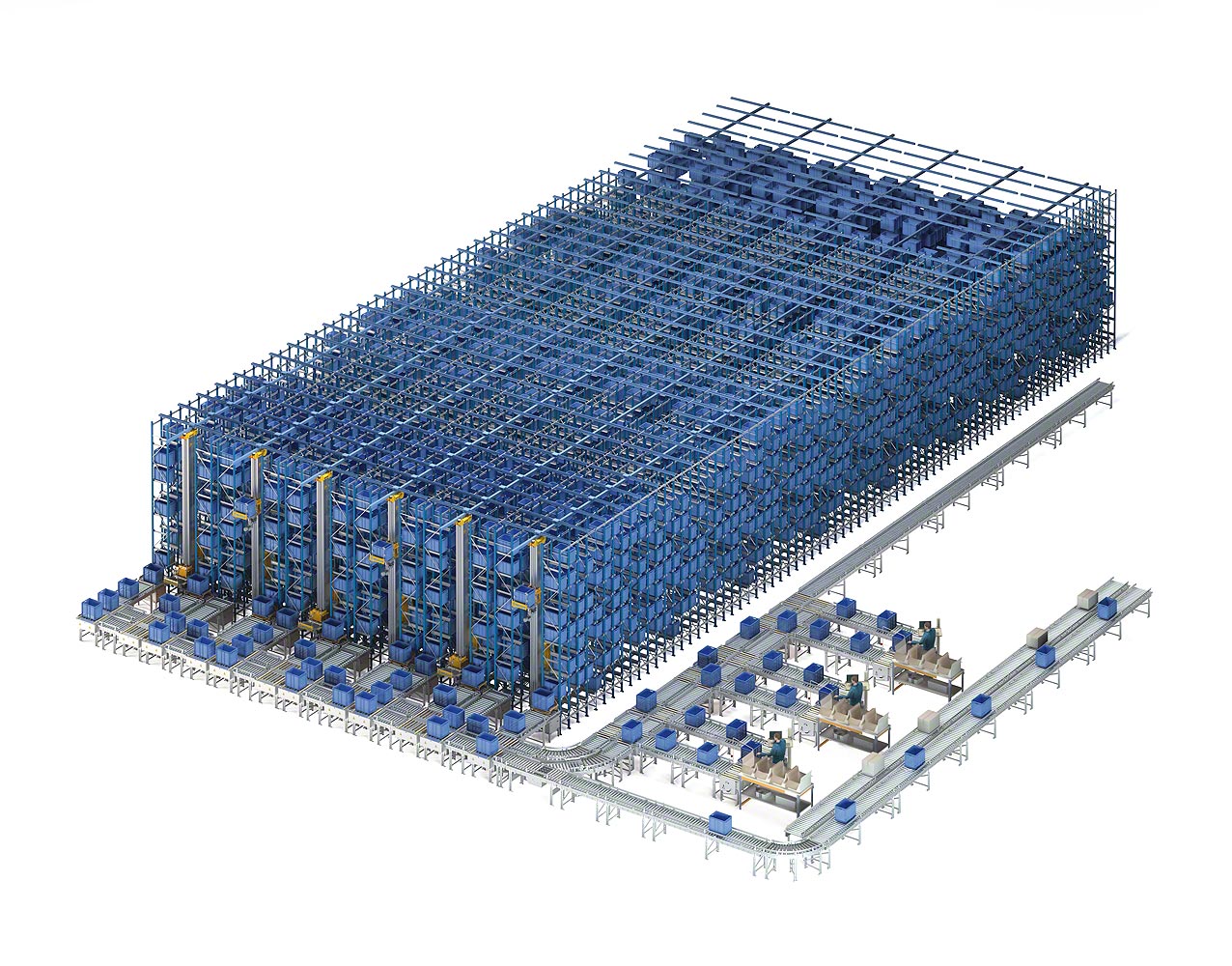

Automated warehouse storage system for boxes or trays that integrates shelving, machinery and warehouse management software all in one. It is made up of a central aisle, along which a stacker crane travels, and two racks built at either side used to store boxes or trays. The picking and handling area is formed by conveyors and is positioned at one end or at the side of the racking. Here, the stacker crane deposits the load extracted from the rack. The conveyors then take the box to the operator and once he/she has finished the job, it is returned to the stacker crane which then places it back in the racking. The whole system is controlled by a management software package which registers the location of all the materials in the warehouse and keeps a real time inventory.

Advantages:

- Applies "product to operator" principle.

- Automation of the entry and exit operations of the products.

- Permanent inventory.

- Eliminating the errors arising from the manual management of the warehouse.

- Optimal use of available space.

- Maximum comfort and easy access to the stored boxes.

Ask an expert