Picking is a pivotal business practice at BMZ Poland

29 May 2017Mecalux will equip the BMZ Poland warehouse in Gliwice (Poland) with a mezzanine and conveyor circuit that will move boxes of goods coming from the production plant.

Mecalux will equip the BMZ Poland warehouse in Gliwice (Poland) with a mezzanine and conveyor circuit that will move boxes of goods coming from the production plant.

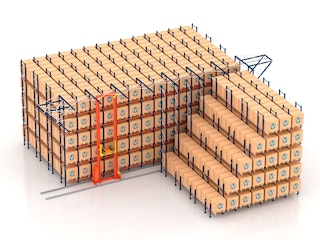

The Belgian company Fritel, specialising in the development and production of fryers, waffle irons, grills and other 'fun cooking' devices, plus the distribution of small appliances, has chosen the Pallet Shuttle system by Mecalux to boost the available space and achieve greater storage capacity.

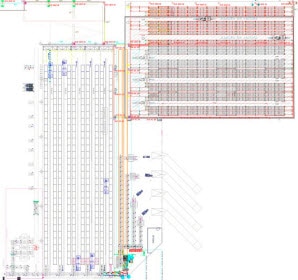

The Portuguese company Cistér will fit out its warehouse in Portugal with the automatic Pallet Shuttle system with transfer car by Mecalux. Through this solution, the company will attain a storage capacity for 12,672 pallets, while achieving a very high inflow and outflow of goods. All operations and processes will be controlled by the Mecalux Easy WMS warehouse management software.

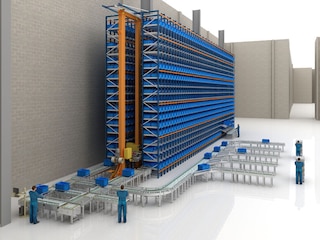

Mecalux has developed new light-duty stacker cranes, of up to 9 m in height, specifically to operate with the Pallet Shuttle system. The automatic Pallet Shuttle solution served by stacker cranes is utilised in warehouses that have few SKUs and many pallets per SKU.

Mecalux will install the semi-automatic Pallet Shuttle system in a new frozen storage installation for Ultracongelados of Cortes. With this solution, the company will expand its storage capacity by about 16,000 pallets of 1,000 x 1,200 mm.

Paolo Astori, an Italian manufacturer of aerospace fasteners, will install an automated miniload warehouse by Mecalux with a storage capacity for 5,472 boxes weighing a maximum of 40 kg each.

The Mecalux showroom, an integral part of the company's new technology centre in Cornellà de Llobregat (Barcelona), has ended 2016 off with a higher number of visitors: more than 800 people have come to see the latest innovations in automated storage solutions.

The future logistics centre of SAM Outillage, a French professional tools manufacturer, will comprise pallet racking and an automated miniload warehouse. The combination of the two storage systems will allow the classification of the merchandise according to its turnover, as well as the organisation of operations, to achieve greater efficiency in picking tasks.

Esnelat (part of the Iparlat group) is a dairy company that was founded in 1953 from a cattle farmer co-op originating from the Basque and Navarro regions.

Following the success of the initiative and the approval in December 2016 of the UPC Chair and Business Classrooms (Aulas de Empresa), a new collaborative agreement for the creation of the Mecalux-UPC Logistics Automation and Innovation Chair was recently signed, which expands and consolidates the relationship between the company and the university.

Mecalux will equip the warehouse of the sporting goods distributor Sportissimo in the Czech Republic with pallet racking and a three-level mezzanine. The principal operation of the warehouse will be preparing online sales orders.

The combination of both systems provides a storage capacity of 19,755 pallets and ensures proper organisation of the goods based on their size and turnover.

In the past two years, about twenty universities have conducted practicums at Mecalux, where the R&D team has tutored final degree and master's projects (mainly the Masters in 'Computer Engineering' and 'Automation Engineering in Industrial Computing' of the EPI and 'Web Engineering' at the School of Oviedo). Most of these students have joined the company's workforce once they have completed the internship.

Mecalux will fit out the Finieco warehouse, a Portuguese paper bag manufacturer, with two blocks of racks served by a light-duty stacker crane and an automatic Pallet Shuttle. In all, the company will attain a storage capacity for 5,000 pallets of 800 x 1,200 mm and 4,700 pallets of 1,000 x 1,200 mm.

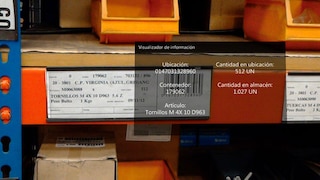

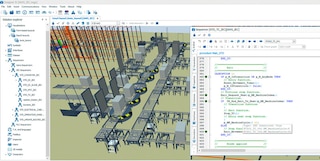

This tool automatically provides a very accurate and authentic 3D graphical representation of the warehouse.

Wawel, will install pallet racking and live racks by Mecalux in its Dobczyce production plant that will allow it to accommodate more than 9,000 pallets.

Mecalux has provided the push-back racking with rollers in the distribution centre that the German publisher Oppermann Druck und Verlags has in the town of Rodenberg.

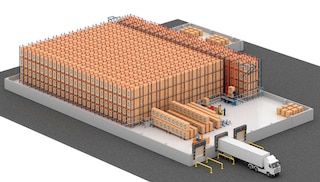

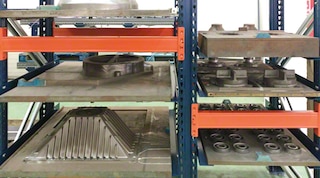

Odlewnia Żeliwa Lisie Kąty, a manufacturer and distributor of iron molds and die cast iron for industrial use, has hired Mecalux to construct a clad-rack warehouse in the town of Grudziądz (Poland) with a storage capacity of more than 7,500 units weighing a maximum of 800 kg.

Spartoo, a European leader in online shoe sales, has again brought Mecalux in to install a platform with walkways for picking. This four-floor set up will quadruple the useful surface area of cell 2 in its warehouse located in Saint Quentin Fallavier (near Lyon, France).

Mecalux, a dedicated LogiMAT attendee, will exhibit its latest products at two visitor stands: one dedicated to storage systems ―prominently the high-performance, high-density Pallet Shuttle system―, while the second will focus on the Easy WMS warehouse management software, developed by Mecalux Software Solutions.